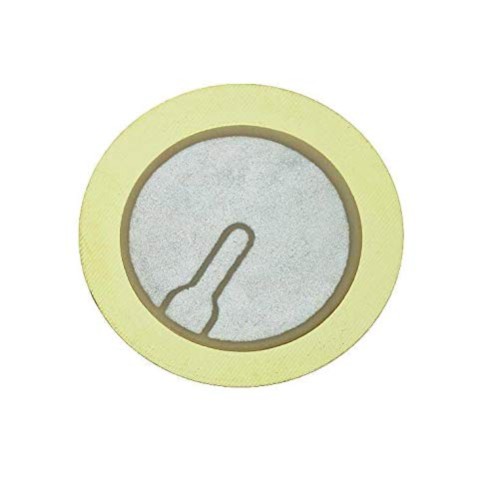

PIEZO SENSORS

Piezoelectric sensors detect an applied force and produce a resultant change in voltage. These types of sensors are capable of detecting various forms of physical quantities including pressure, vibration, acceleration, displacement and compression

₹ 12 ₹19

19

Add FAQ

Piezo sensors are devices that use the piezoelectric effect to measure pressure, force, or vibrations. When mechanical stress is applied to a piezoelectric material, it generates an electrical charge that can be measured and used to infer the amount of pressure or force. Piezo sensors are widely used in various applications due to their sensitivity, fast response time, and ability to detect a wide range of forces.

Key Features of Piezo Sensors

- Piezoelectric Effect: Converts mechanical stress into an electrical signal.

- Sensitivity: Can detect small changes in pressure or force due to high sensitivity.

- Frequency Response: Capable of detecting rapid changes, making them suitable for applications requiring high-frequency response.

- Durability: Often robust and able to operate in harsh environments.

- Compact Size: Generally small and lightweight, making them easy to integrate into various systems.

Types of Piezo Sensors

- Piezoelectric Accelerometers: Measure acceleration or vibration by detecting changes in force applied to a sensor element. Commonly used in automotive and aerospace applications.

- Piezoelectric Pressure Sensors: Measure pressure changes and are used in various industrial applications, including fluid dynamics and process control.

- Piezoelectric Force Sensors: Detect force or load by measuring the stress applied to the sensor. Useful in testing and measurement systems.

- Piezoelectric Vibration Sensors: Detect vibrations and are used in machinery condition monitoring and structural health monitoring.

Applications

- Industrial Automation: Used for monitoring equipment vibrations, force measurements, and quality control.

- Consumer Electronics: Found in devices like microphones, accelerometers in smartphones, and touch-sensitive controls.

- Medical Devices: Used in medical ultrasound equipment and other diagnostic tools.

- Automotive Industry: Applied in vehicle vibration monitoring and impact detection systems.

- Aerospace: Utilized for monitoring structural health and detecting vibrations in aircraft.

Basic Operation

- Mechanical Stress Application: When mechanical stress (force, pressure, or vibration) is applied to the piezoelectric material, it deforms slightly.

- Charge Generation: This deformation generates an electrical charge proportional to the applied stress.

- Signal Measurement: The generated electrical signal is then measured and processed. This signal can be directly read or converted into a meaningful unit of measurement using appropriate circuitry.

Example Use Case

Here’s a simple example of how a piezo sensor might be used in an Arduino project to detect taps or knocks:

const int piezoPin = A0; // Analog pin connected to the piezo sensor

int sensorValue = 0; // Variable to store the sensor value

void setup() {

Serial.begin(9600); // Initialize serial communication

}

void loop() {

sensorValue = analogRead(piezoPin); // Read the value from the piezo sensor

Serial.println(sensorValue); // Print the sensor value to the serial monitor

delay(100); // Small delay to prevent flooding the serial monitor

}

In this example, the piezo sensor is connected to an analog input pin on an Arduino. The sensor value is read and printed to the serial monitor. When a tap or knock is detected, the sensor value will change accordingly.

Considerations

- Sensitivity Calibration: Depending on the application, you may need to calibrate the sensor to ensure accurate measurements.

- Signal Conditioning: Piezo sensors often require signal conditioning, such as amplification or filtering, to provide usable data.

- Temperature Effects: The piezoelectric effect can be influenced by temperature, so compensation may be necessary in some applications.

If you have specific questions about piezo sensors or need assistance with a particular application or integration, feel free to ask!

0 Reviews For this Product

.jpg&width=225&quality=80)